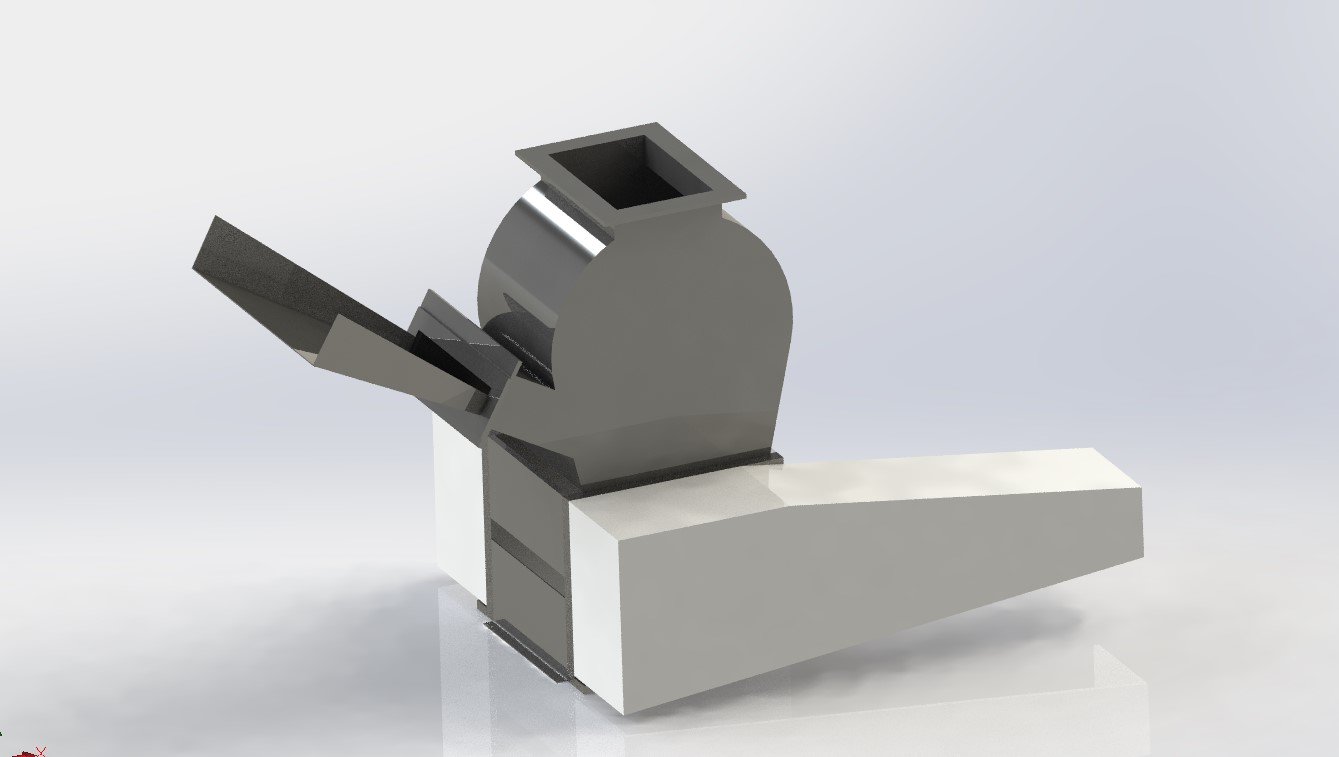

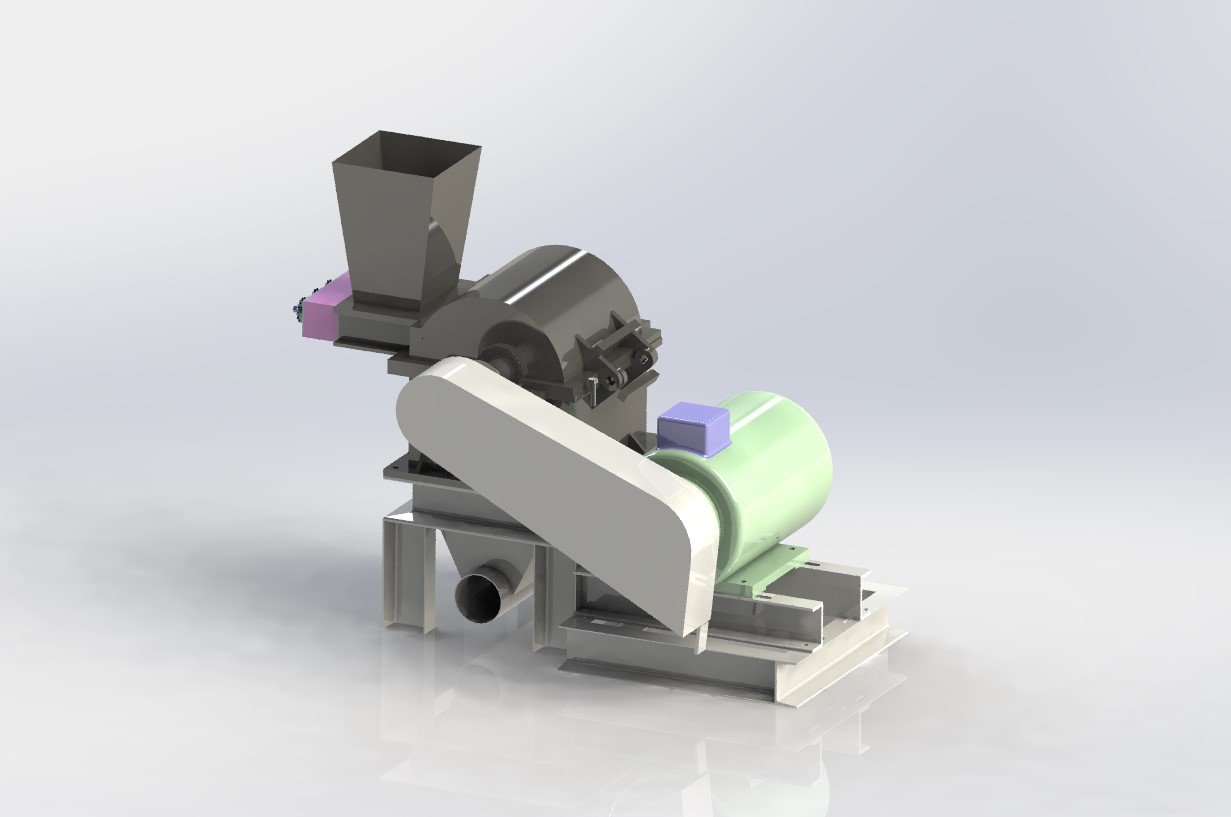

Chopper

The Chopper machine is designed to crush the material into small pieces or granules. This system is most efficient where there is requirement of granules, tbc, flakes, etc. The system is designed in such a way that there is no heat generation and very less powder content as compared to other pulverizer. In this machine, there are 2 fixed blades on 2 sides and rotating blades on the shaft between which the material is being cut / crushed. This system is widely used for Tea cut products and for crushed chili for pizza toppings (Chili flakes). Some other applications for which the machine is used are ayurvedic herbs, onion flakes, granulations for food colors, etc. The capacity ranges from 40 to 50 kg/hr to 2 Ton/hr.

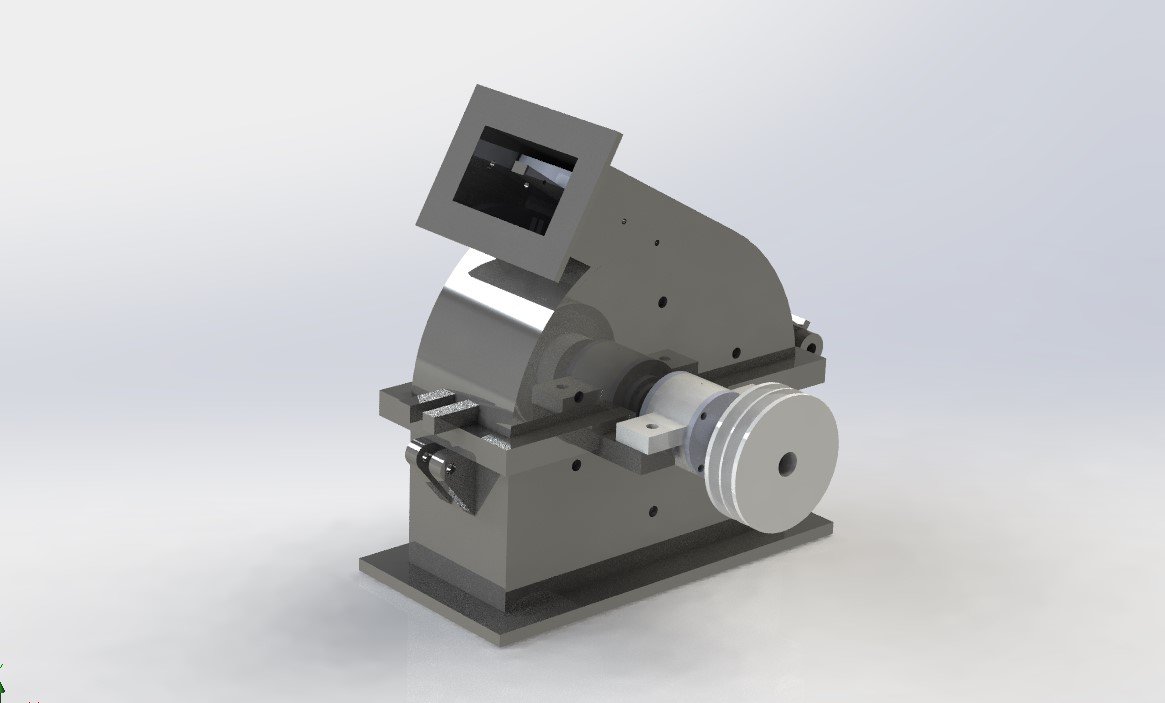

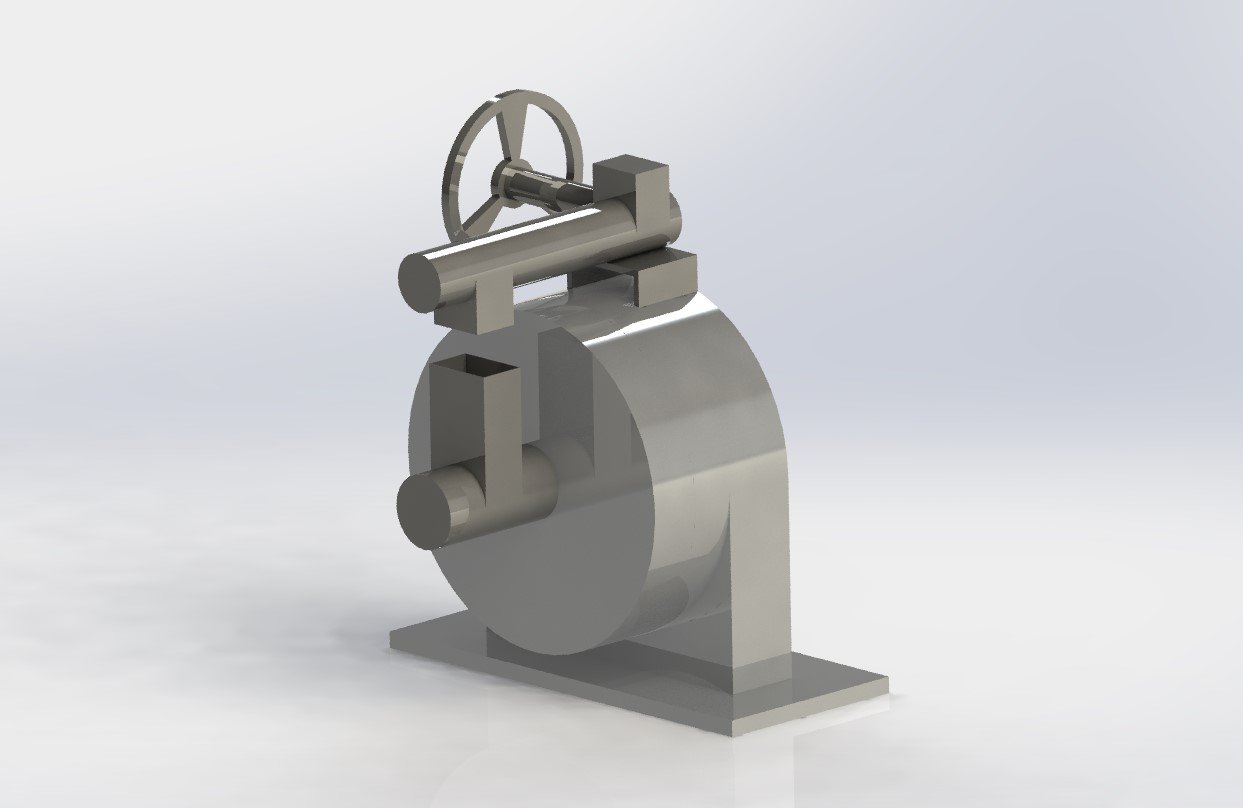

Hammer Mill

The Hammer mill is the most efficient pulverizer used for size reduction of various application viz. Spices, Chemicals, Minerals, Pharmaceuticals, Ayurvedic, etc. It can be used for wide range of material ranging from friable, non - friable, fibrous, etc. The grinding takes place between the high-speed swinging hammers and top/side liners. Once the particle size reduces to that of the perforated screen at the bottom, it will be discharged through the hopper. The fineness achievable in this system will be 15 to 60 Mesh BSS (depending on the physical properties of the material). The capacity ranges from 40 to 50 kg/hr to 1.5 Ton/hr.

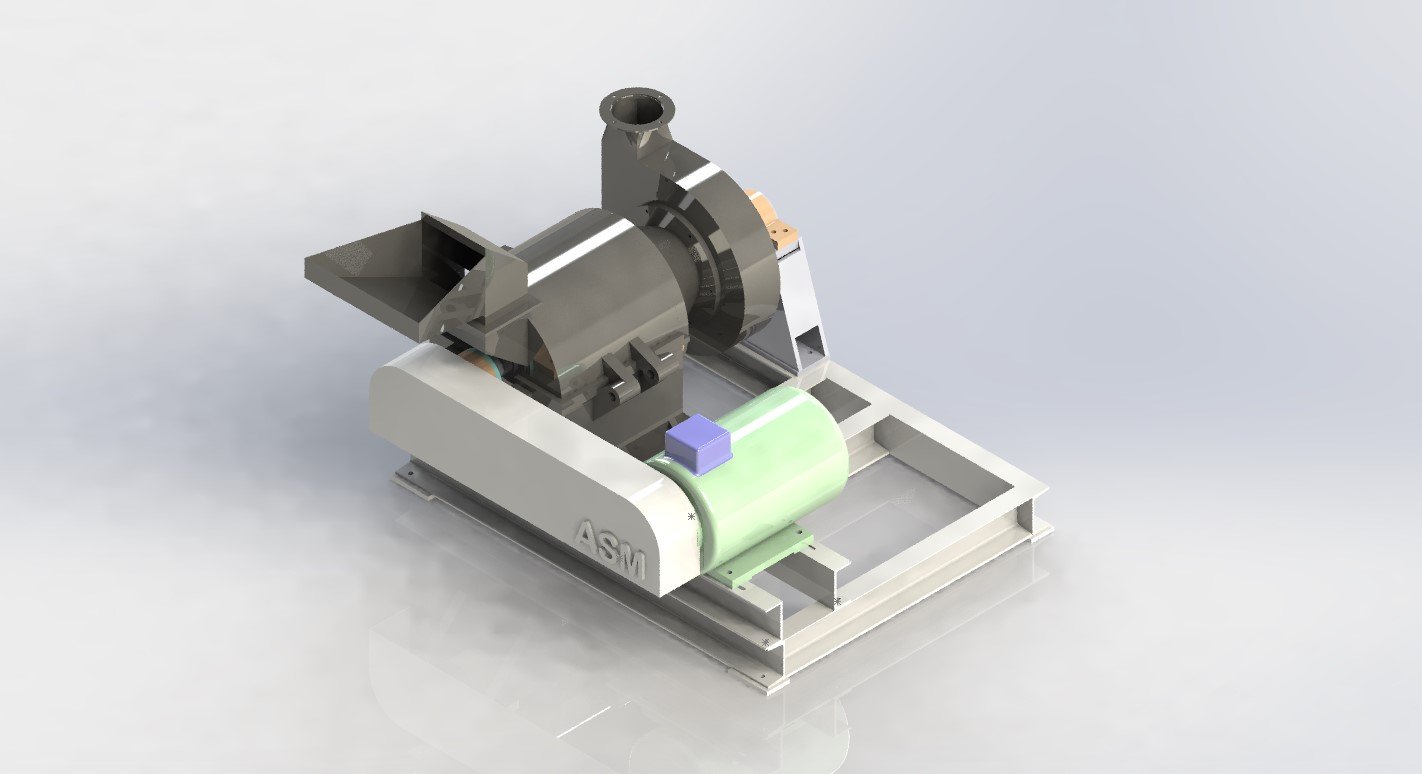

Pin Mill

The Pin Mill is used for fine grinding of soft to semi solid material. The heat generation in this system at the time of grinding is very low compared to other pulverizers. This ensures prevention of vital properties like aroma, taste, etc. This grinding system is used in pulverizing, wet grinding, deagglomeration, etc. The material is centrally fed and grinding takes place in between high speed rotors consisting of pins and a stationary stator. The discharge takes place through perforated screen. The capacity ranges from 100 kg/hr to 2 Ton/hr.

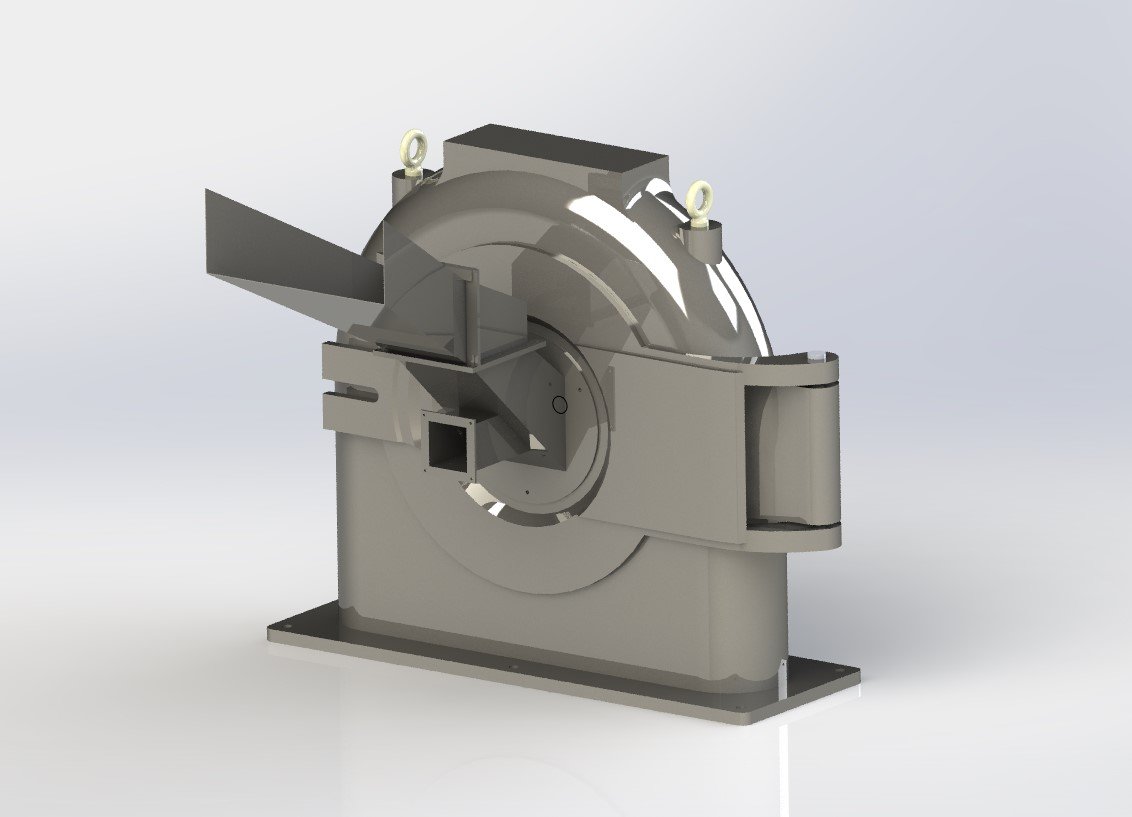

Air Swept Mill

The Air Swept Mill is a screenless pulverizer which is used to micro grinding of brittle, fibrous, soft to medium hard material. In this system, the grinding takes place between the serrated liners and high speed hammers. The material is then sucked by the blower before which there will be whizzer classifier which allows only the micro powder to pass through thereby trapping the oversized material. This system is best suited for grinding of turmeric fingers, grains, etc. The capacity ranges from 40 kg/hr to 2 Ton/hr.

Micro Pulverizer

The Micro Pulverizer is used to grind soft to medium hard material into fine powder. This is system is widely used for applications like spices, pharmaceuticals, dyes, icing sugar, etc. The grinding takes place between high speed stirrup type hammer and serrated liner. The material is discharged through sieve. The capacity ranges from 40 kg/hr to 1 Ton/hr.

Ultra Fine Mill

The Ultra Fine mill is a screenless pulverizer used to grind soft to medium hard material into very fine powder. This system has built in water jacket to maintain the temperature inside the grinding chamber. The grinding takes place due to attrition between high speed wear resistant tips and liners on both the side along with turbo (jet) effect. The material is discharged through annular gap plate through which the flow of material is controlled. The capacity ranges from 30 kg/hr to 200 kg/hr.